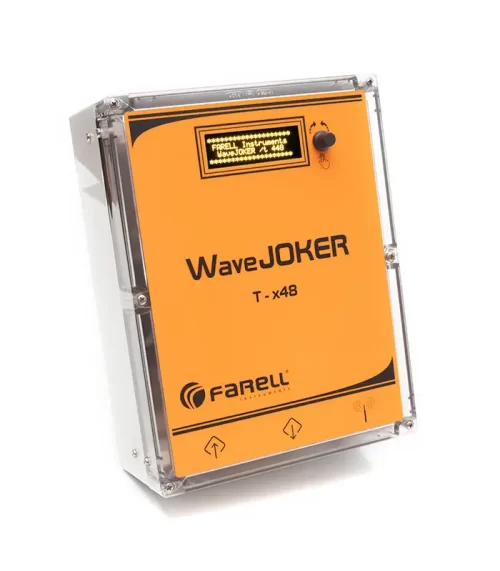

WAVEJOKER

Remote control system for water supply networks

Remote control system for water networks, such as tanks, pumps or distribution networks. The system allows autonomous and centralized operation modes based on WAVEJOKER units and other equipment (PLC, specific measurement equipment, etc.).

Integrable into any remote control installation or SCADA system with Modbus protocol.

KEY CONCEPTS

Available in VHF and UHF bands with license or in free band. Without dependence on mobile coverage or network operators. Protocol Modbus (permet encriptació).

Easy installation and configuration equipment

Configuration through the display of the unit itself. Includes test functions and quality measurements for radio links. Configuration and immediate start-up.

Autonomous and integrable

Autonomous operation and also integrable into any SCADA with Modbus support.

Low consumption

Battery-powered storage units with extremely low consumption, even with power from analog sensors, integrated display and long-range radio communications. Battery life of more than 3 years.

Specific

Without programming, it incorporates all the functions necessary to control the supply network (communications, pumps, tanks, network points, valves, etc.).

APPLICATIONS

· Water supply networks.

· Remote control of purification networks.

· Industrial remote control.

· Reservoirs.

· Autonomous control of pumping to tank.

· Remote control.

· Integration of canalization to irrigation systems.

CHARACTERISTICS

· Pumping station unit with control up to 6 pumps (P unit).

· Pumping control for local and remote tank with energy savings, based on different tank filling levels according to current electricity rate.

· Pump rotation.

· Alternate pump if failure.

· Hour counter and maneuvers.

· Total water and flow meters.

· Total water and flow meters.

· Integrated multi-rate clock (summer/winter).

· Self-calibrated tank level measurements.

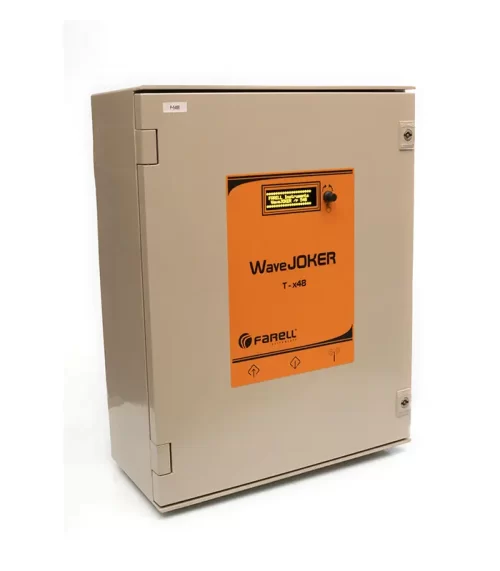

· Wall mounting box.

· Wide temperature range (-30 ºC to 65 ºC).

· Integrated native Modbus.